Address

the cross of hualong road and beijing road,Hedong district,Linyi City,Shandong,China

Work Hours

Monday to Friday: 8AM - 6PM

Weekend: 9AM - 5PM

Address

the cross of hualong road and beijing road,Hedong district,Linyi City,Shandong,China

Work Hours

Monday to Friday: 8AM - 6PM

Weekend: 9AM - 5PM

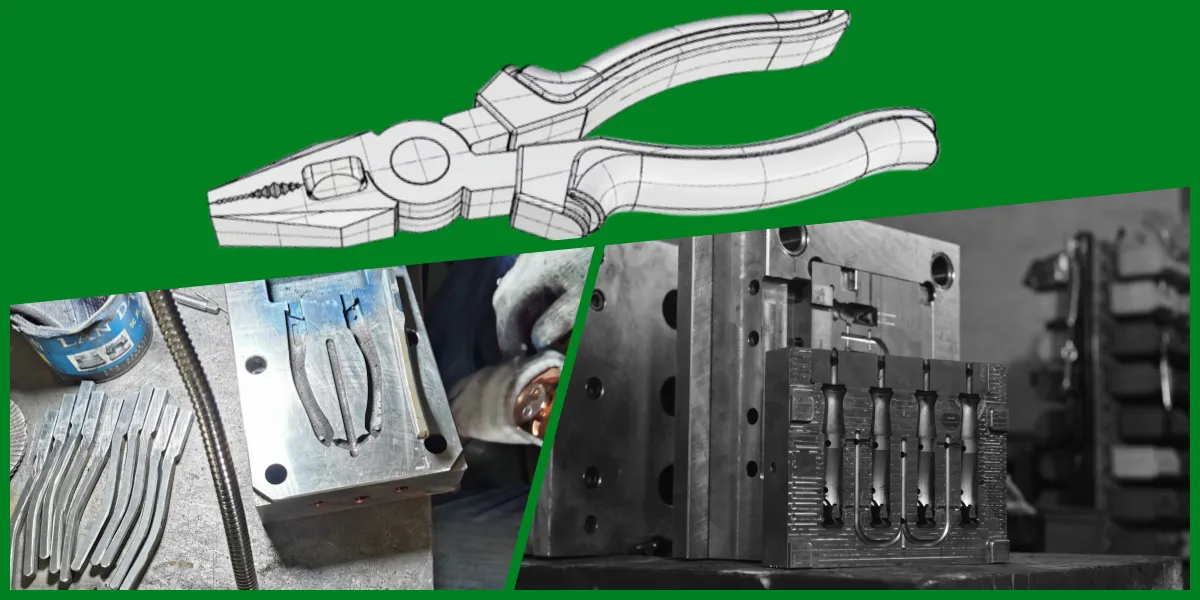

We design & produce pliers of various styles.

Linyi Beyond Tools Co., Ltd. was founded in 2008.which has more than 15 years of experience in hand tools field, Our company has been the professional manufacturer of pliers and other hand tools, with an annual capacity of 5 million pieces of pliers. Our company just focus on the manufacturing of combination plier,long nose plier, diagonal plier and multifunctional plier, we do not manufacture various pliers, be the expert and top manufacturer in one item is our mission of the craftsmanship spirit. Our continuous persever-ance in providing quality products & services has earned the good reputation in plier field across the globe.

Our factory has 5000 square meters workshop that is locatedin Linyi City, Shandong Province of China (around 3hours/200kms far from QINGDAO PORT). Producing high quality pliers with over 400,000 pieces each month as per international standards that meet our customers’ requirement. Supplying consistent quality, timely delivery & best service is our permanent mission.

Main products: combination plier, long nose plier,diagonal plier and multifunctional plier with annual capacity of 5 million pieces. Our items are widely exported to over 30 major countries in North and South America, South Asia, South-east Asia and Middle East.

We hereby send our NEW CATALOGUE to you, which covers most of our products. We sincerely thanks for your time reading our catalogue and hope it can help your working & saving time in searching for good suppliers. Welcome to contact us for more inquiry and Best Regards. All staff from Shandong Beyond Machinery Co.,Ltd.

Our company has a professional mold design and manufacturing department. The designer has many years of experience in hand tool design, and can design according to customer needs. After meeting customer requirements, we can make molds according to the design. it is important to follow the keys:

● Clearly understanding customer’s needs and preferences after contacting with customers

● Create the design brief

● Sketch out initial design ideas

● Present the initial designs to customers

● Refine & finalize the designs

High degree of automation, very high production efficiency. Except for blank clamping, all other processing procedures can be completed by CNC machine tools. It can greatly improve the processing accuracy, including processing quality accuracy and processing time error accuracy, and can stabilize the processing quality and maintain the quality of processed parts.

● Safe processing

● Small error

● High precision

● Process complex surfaces

● High flexibility

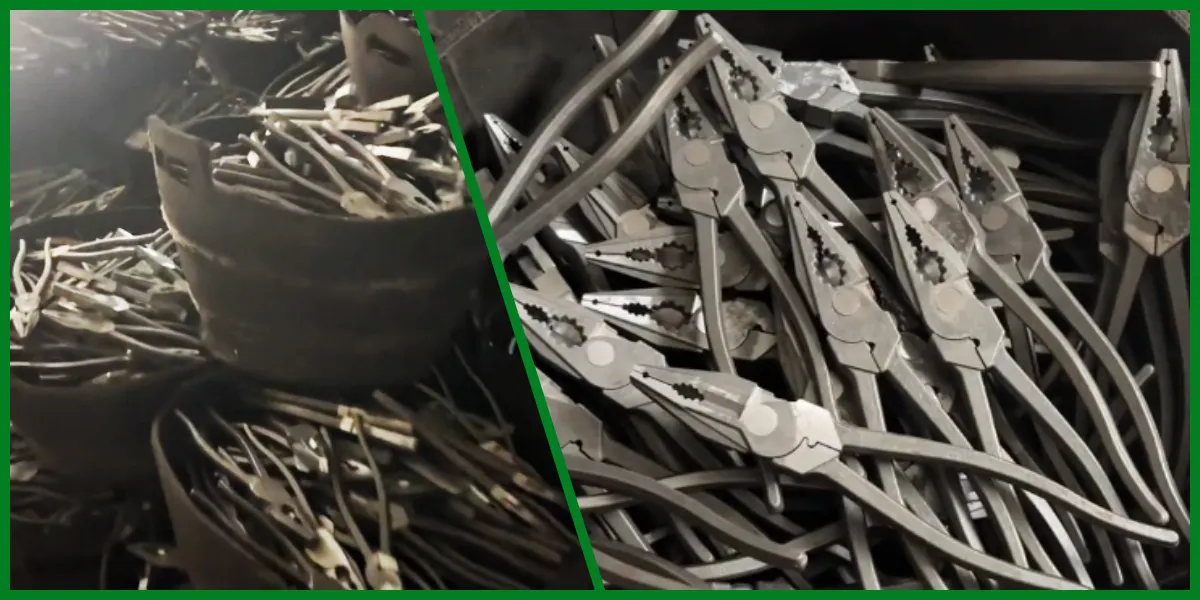

Forging refers to the process of forging pliers produced by metal in a red-hot state through air hammers or presses and other equipment. The pliers processed by forging have high hardness, sharp wear resistance, good texture and good corrosion resistance, which can ensure that the pliers have good mechanical properties and long service life

● Improve material properties

● High processing precision

● Good extensibility

● low energy consumption

A metal thermal processing process in which the material is in a solid state by means of heating, heat preservation and cooling to obtain the desired structure and properties. Metal heat treatment is one of the important processes in mechanical manufacturing. Compared with other processing techniques, heat treatment generally does not change the shape and overall chemical composition of the workpiece, but changes the microstructure inside the workpiece or changes the chemical composition on the surface of the workpiece, to give or improve the performance of the workpiece. It is characterized by improving the intrinsic quality of the workpiece, which is generally not visible to the naked eye. In order to make the metal workpiece have the required mechanical properties, physical properties and chemical properties. The 62-meter heat treatment line in our factory can make the pliers get better hardness, toughness, wear resistance and other properties

Surface treatment is to form a surface layer with one or more special properties on the surface of materials by physical or chemical methods. Surface treatment can improve product appearance, texture, function and other aspects of performance. Metal wire drawing: By grinding the product to form lines on the surface of the workpiece, the wire drawing treatment can make the metal surface obtain a non-mirror-like metallic luster, and at the same time, the wire drawing treatment can also eliminate fine defects on the metal surface. Electrophoresis: It can make the product appear in various colors and maintain the metallic luster, while enhancing the surface performance and having better anti-corrosion performance.

● Anti-corrosion, anti-oxidation

● Protect the surface, scratch-resistant and wear-resistant

● Decorative effect, beautiful

● Improve surface hardness

The handle is assembled to the pliers, and packed according to customer requirements. The general conventional packing method is: plastic elevator/blister, inner box, outer box. Ensure the integrity of the pliers packaging during shipping.

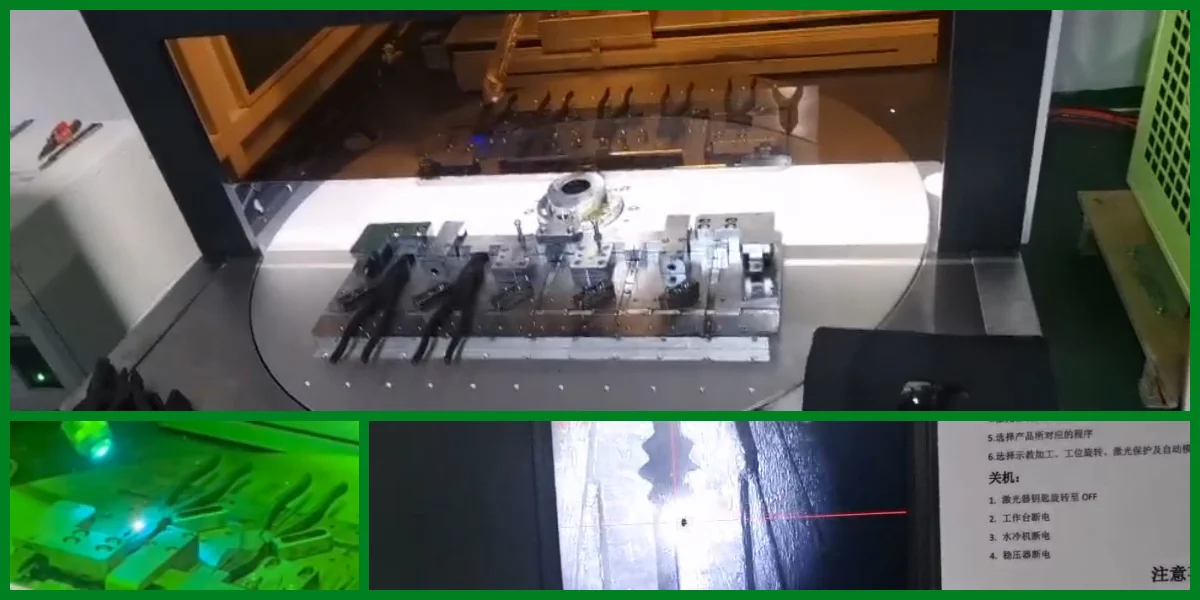

Laser quenching or laser phase change hardening is to quickly scan the workpiece with a high-energy laser beam, so that the surface temperature of the irradiated metal or alloy rises above the phase transition point at an extremely fast speed. When the laser beam leaves the irradiated part, due to the effect of heat conduction, The matrix in the cold state makes it cool rapidly for self-cooling and quenching to obtain a finer hardened layer structure, and the hardness is generally higher than that of conventional quenching. The deformation of the workpiece is extremely small during the treatment process, and it is suitable for surface strengthening of some workpieces or partial parts of the workpiece that cannot be completed or difficult to achieve by other quenching techniques. Laser heat treatment has a high degree of automation, and the controllability of the depth of hardened layer and hardened area is good. After laser treatment, the surface hardness of cast iron can reach above HRC60 degrees, and the surface hardness of medium carbon and high carbon carbon steel can reach above HRC70 degrees, so as to improve the performance of wear resistance, fatigue resistance, corrosion resistance and oxidation resistance, and prolong its service life.

● Improve surface hardness

● Excellent wear resistance

● Excellent corrosion resistance

● Excellent anti-fatigue

● Excellent antioxidant

Our items are widely exported to over 30 major countries,such as North and South America, Middle East, South Asia and South-east Asia. The continuous in providing quality products & services of our factory has earned the good reputations in plier field across the world.